regeneration

We can’t just sit around and wait to see what will happen next. We need positive action.

I’ve read a lot of Climate Adaptation Plans and Strategies over the past the last few years, but He Toka Tū Moana Mō Maketū (Maketū Climate Change Adaptation Plan) is hand-down the best. It’s clearly laid out, outlines the community’s priorities, and can readily serve as a template to help every community around Aoteara develop their own Climate Adaptation Plans. Most important of all:

It’s iwi led, community driven, it’s a plan that’s been decided by those who live here. – Elva Conroy, Kaitohotohu / Facilitator (Video; to listen Watch on Youtube)

Winner of the 2023 Supreme Planning Awards, the Maketū Climate Change Adaptation Plan was developed by Ngāti Pikiao Environmental Society, Te Rūnanga o Ngāti Whakaue ki Maketū , Whakaue Marae Trustees, and Conroy and Donald Consultants.

In the words of the Maketu Iwi Collective, ‘we will be resilient like the anchor stone Takaparore – strong and steadfast against the elements and tides of change and uncertainty. Regardless of what happens as a result of a changing environment, we will remain standing’. – New Zealand Planning Institute, April 2023.

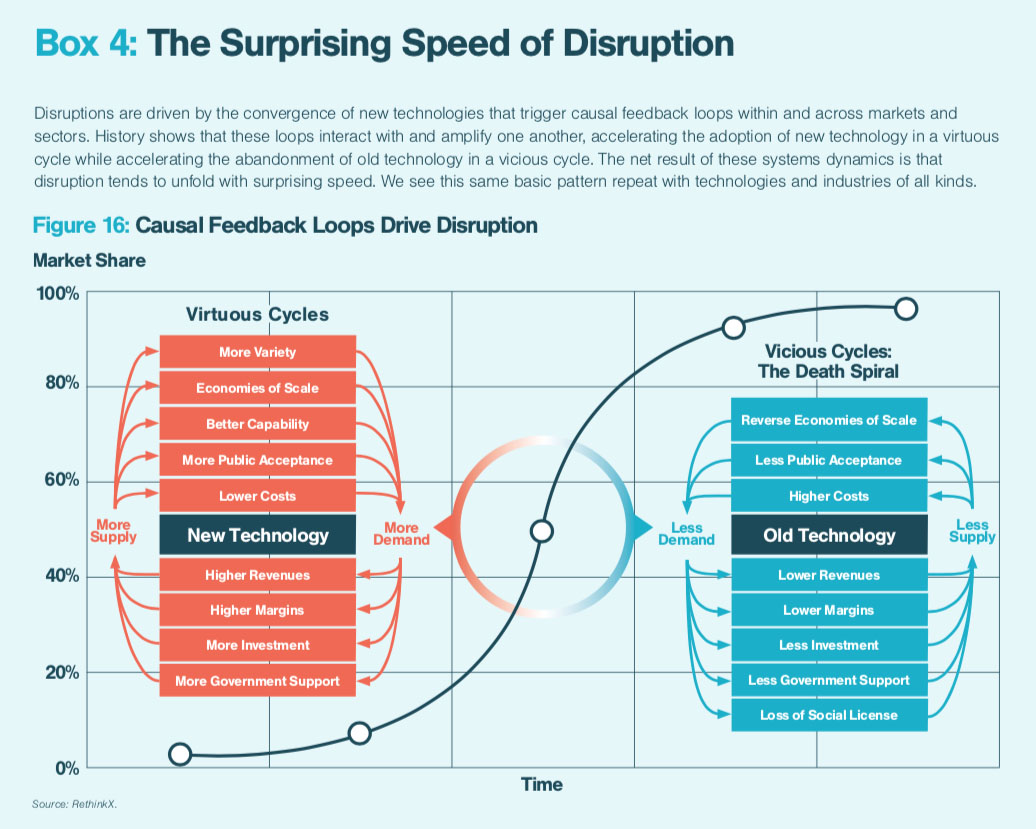

The whole of the cow milk industry, for example, will begin to collapse once PF [precision fermentation] technologies replace the proteins in a bottle of milk–just 3.3% of its content. Product after product that we extract from animals will be replaced by superior, cheaper, cleaner, and tastier alternatives, triggering a death spiral of increasing prices, decreasing demand, and reversing economies of scale for the livestock and seafood industries. – RethinkX

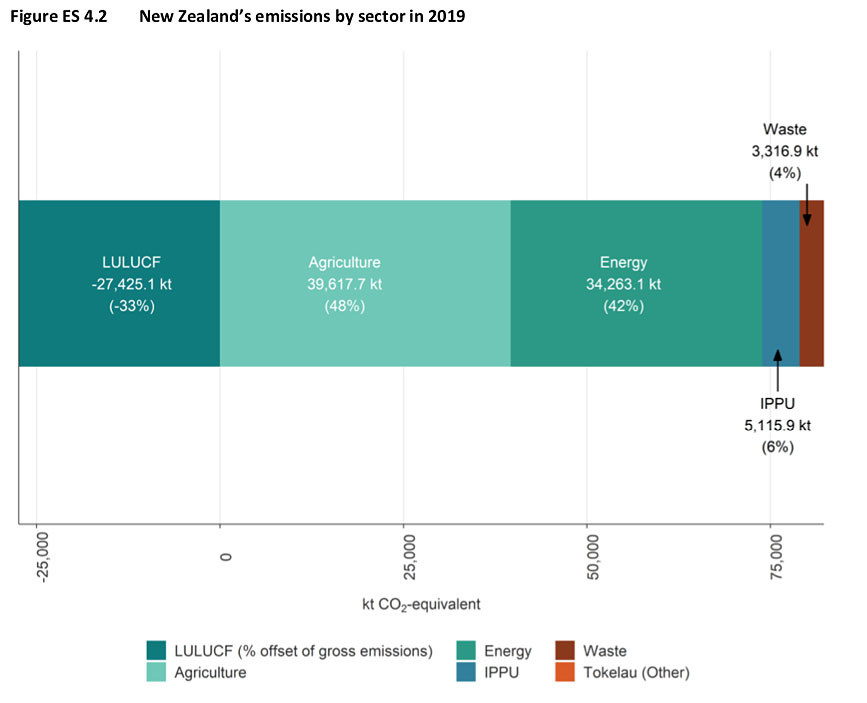

One of the key recommendations from IPCC to rapidly reduce greenhouse gas emissions, is to change our diets, particularly away from animal protein, primarily meat and dairy. This because growing animal protein produces a staggering volume of greenhouse gasses—48% of New Zealand’s emissions come from this sector.

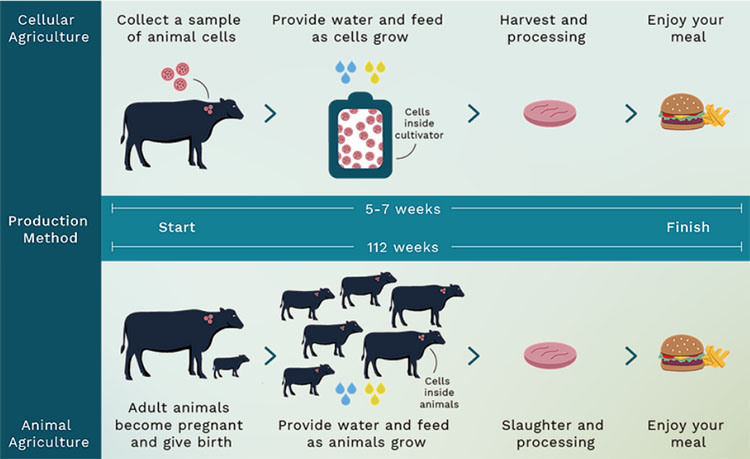

Not everyone is prepared to give up meat and dairy of course, something of which the food industry is well aware. This has led to a rapid growth (no pun intended) in the cellular versus animal agriculture industry. Motif is one of dozens of these fast-growing disruptive technologies that aim to drastically reduce greenhouse gas emissions and enable intensively farmed land to be returned to natural ecosystems, which also means cleaner waterways. At its simplest level, this is how it works:

There’s a more in-depth discussion of cellular and acellular processes on the Office of the Prime Minister’s Chief Science Advisor website: cellular agriculture.

RethinkX‘s paper, ‘Rethinking Climate Change’ examines the speed of disruptive technologies in the energy, food, and transport sectors (from page 30):

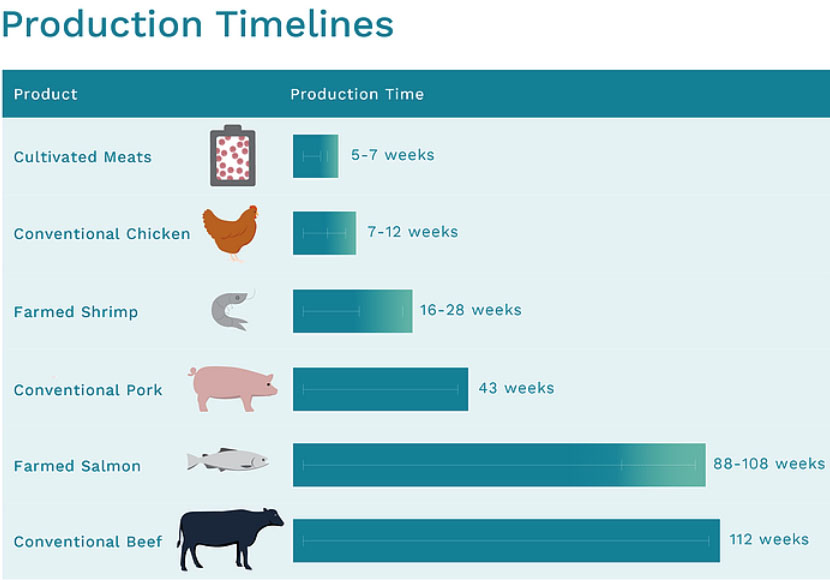

The food disruption will be driven by the economics of precision fermentation (PF) and cellular agriculture (CA), which will compete with animal products of all kinds. Our previous research found that PF will make protein production 5 times cheaper by 2030 and 10 times cheaper by 2035 than existing animal proteins. The precision with which proteins and other complex organic molecules will be produced also means that foods made with them will be higher quality, safer, more consistent, and available in a far wider variety than the animal derived products they replace. The impact of this disruption on industrial animal farming will be profound.

The economic competitiveness of foods made with PF technology will be overwhelming. As the most inefficient and economically vulnerable part of the industrial food system, cow products will be the first to feel the full force of the food disruption. New PF foods will be up to 100 times more land efficient, 10-25 times more feedstock efficient, 20 times more time efficient, and 10 times more water efficient. They will also produce far less waste. By 2030, the number of cows in the United States will have fallen by 50% and the cattle farming industry will be all but bankrupt. All other commercial livestock industries worldwide will quickly follow the same fate, as will commercial fisheries and aquaculture.

This staggering transformation will present an entirely unprecedented opportunity for conservation, rewilding, and reforestation.